Maintenance teams often don't realize how much their work order process costs them until something breaks down. Not the equipment, but the process itself.

The signs appear gradually. A request gets lost. A technician arrives without the right parts. A manager spends hours compiling reports that should take minutes. Each incident seems minor in isolation. Together, they reveal systemic problems that drain productivity every single day.

Recognizing these warning signs early can save organizations significant time and money. Here are five indicators that your current work order management approach has outgrown its usefulness.

1. Requests Disappear Into the Void

Someone reports a problem. Days pass. The requester calls back, frustrated, asking what happened. Nobody knows.

This scenario plays out constantly in organizations relying on email, phone calls, or paper forms for maintenance requests. Without a centralized intake system, requests depend on individual memory and manual tracking. Things slip through cracks because cracks are everywhere.

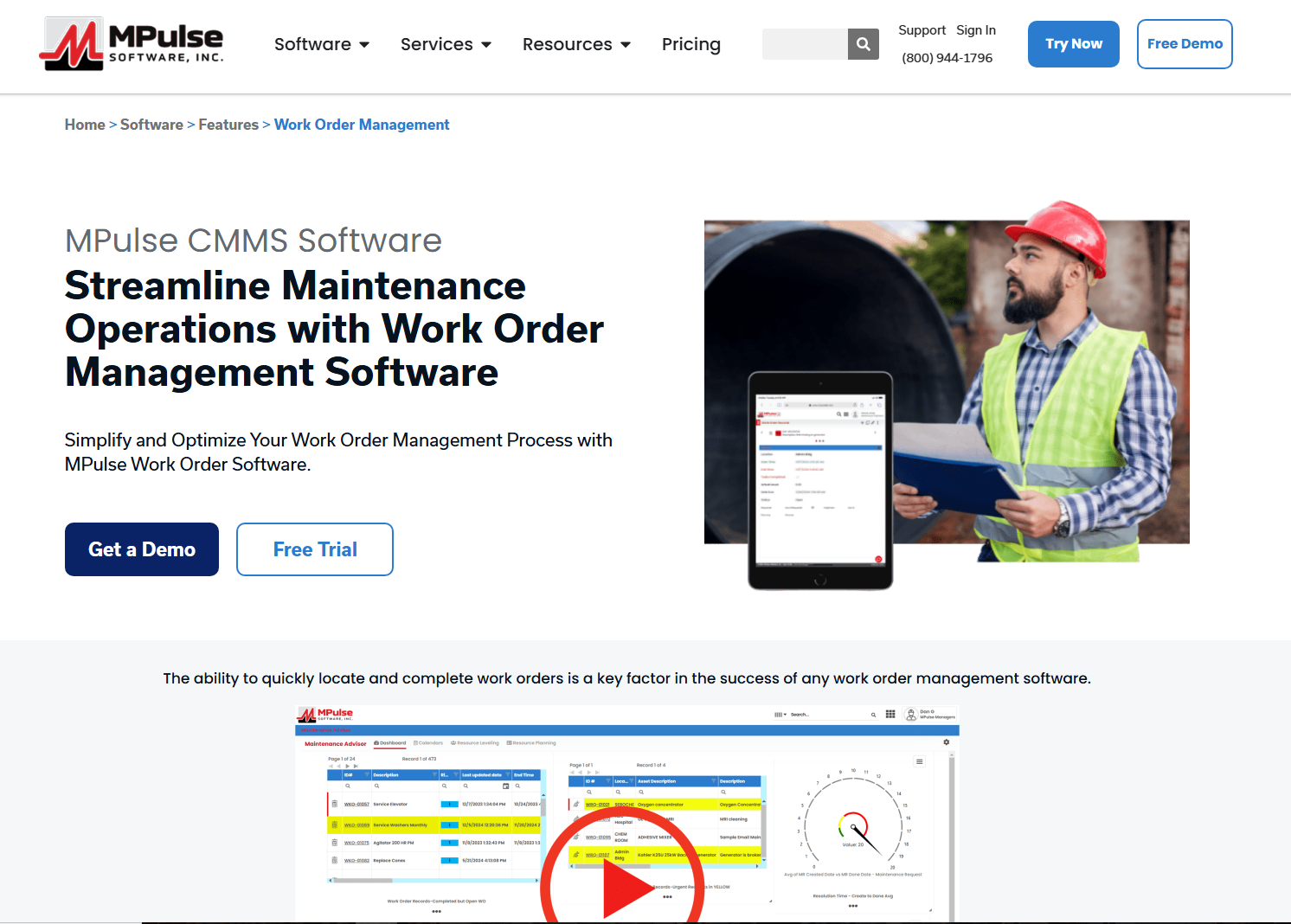

Effective work order software eliminates this problem by creating a single entry point for all requests. Every submission gets logged, timestamped, and tracked through completion. Nothing disappears because the system won't let it.

2. Dispatching Feels Like Guesswork

Which technician should handle this repair? Who has the right skills? Who's already nearby? What's their current workload?

Without visibility into these factors, dispatchers make educated guesses. Sometimes they guess wrong. A senior electrician gets sent to change light bulbs while a complex electrical issue waits for whoever happens to be available.

Modern work order management solutions like MPulse track personnel qualifications, certifications, and current assignments in real time. The system can prioritize and assign work orders based on urgency and skill requirements, ensuring the right person handles each job.

3. Equipment History Lives in Someone's Head

A machine fails. The technician who knows its quirks retired last year. Current staff start troubleshooting from scratch, unaware this same problem occurred three times previously with a documented solution.

When maintenance history exists only in institutional memory, organizations lose it constantly. Staff turnover, shift changes, and simple forgetfulness all erase valuable information.

Work order software maintains complete equipment histories automatically. Every repair, every part replacement, every inspection finding links to specific assets permanently. New technicians access decades of accumulated knowledge instantly.

4. Reporting Requires Archaeology

Budget season arrives. Leadership wants maintenance cost breakdowns by equipment type, building, and department. The maintenance manager starts digging through spreadsheets, filing cabinets, and email archives. Days later, they produce numbers they don't entirely trust.

Manual reporting consumes time that should go toward improvement activities. Worse, the effort often produces incomplete or inaccurate information because source data is fragmented and inconsistent.

Centralized work order systems capture data once and report it infinitely. Dashboards display real-time metrics. Custom reports generate in minutes. Managers spend time analyzing information rather than hunting for it.

5. Preventive Maintenance Keeps Slipping

The preventive maintenance schedule exists. It's posted on the wall, saved in a spreadsheet, maybe even printed in a binder. But execution? That's another story.

Reactive emergencies consume available labor. Scheduled tasks get pushed back. Nobody notices until equipment fails and someone asks why the PM wasn't completed.

Work order software automates preventive maintenance scheduling and tracks compliance relentlessly. The system generates work orders automatically, flags overdue tasks, and provides visibility that makes schedule slippage impossible to ignore.

The Cost of Waiting

Every week spent with inadequate work order management accumulates hidden costs. Technician time wasted on preventable confusion. Equipment failures that proper tracking would have predicted. Management hours consumed by manual processes that software handles automatically.

Organizations that recognize these warning signs and act on them gain competitive advantages that compound over time. Those that dismiss the signs as "just how things work" continue paying costs they never fully see.

The question isn't whether better work order management would help. The question is how much longer you can afford the alternative.

Leave a Reply